Position:Home > Outdoor fire-retardant

Position:Home > Outdoor fire-retardant

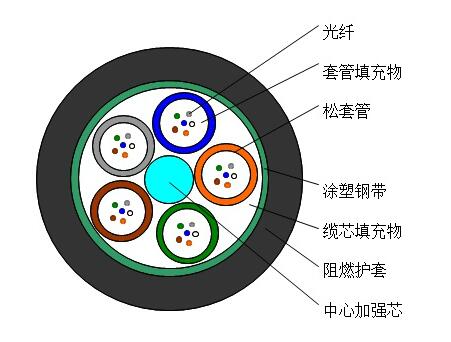

The fibers, 250m,are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant Ring compound.A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and Hers) are stranded around the strength member into a compact and circular cable core. The PSP is longitudinally applied over the cable core, which is filled with the Ring compound to product it from water ingress. The cable is completed with a flame一retardant sheath.

Good mechanical and temperature performance

High strength loose tube that is hydrolysis resistant

Special tube filling compound ensure a critical protection of fiber

Special sheath material ensure excellent flame-retardant performance

Crush resistance and flexibility

Special designed compact structure is good at preventing loose tubes from shrinking

The following measures are taken to ensure the cable watertight:

1.Steel wire used as the central strength member

2.Loose tube filing compound

3.100% cable core filing

4.PSP enhancing moisture-proof

5.Water-blocking material